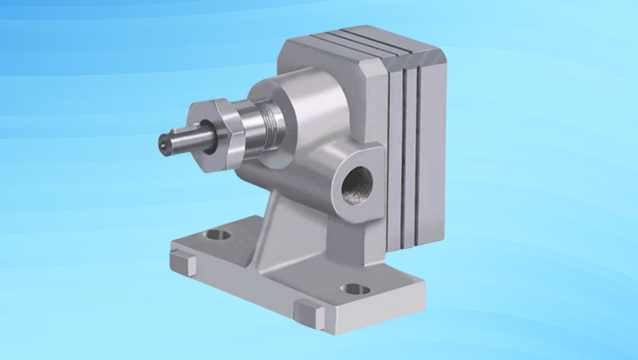

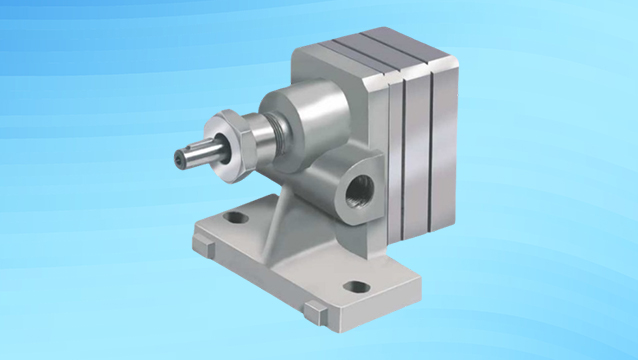

PU Pumps / Polyurethane Pumps

Alfa Pumps and Systems is recognized as one of the leading Manufacturer and Supplier of PU Pumps.

We have introduced PL Series Pumps which are widely used in Polyurethane and Rayon Industries like Casting, Foaming, Spraying, Coating, Sealing, Adhesive etc. Common applications include spraying PU foam for insulation, injecting PU for sealing and bonding, and applying PU coatings for protection and finishing.

PU Pumps, or Polyurethane Pumps, are a type of pump specifically designed to handle polyurethane (PU) materials. Components like metering units, mixing heads, and spray guns are used for manufacturing PU Pumps. These components ensure accurate mixing and dispensing of polyurethane.

These pumps are used in various industries, including automotive, construction, and manufacturing, to dispense and apply polyurethane for different purposes such as insulation, sealing, and coating.

In Material Handling, PU Pumps are engineered to handle the unique properties of polyurethane, which can be viscous and reactive. The pumps ensure smooth and consistent flow of the material.

Features of PU Pumps :

- High Accuracy : Stable , repeatable flows are assured even under varying conditions of pressure, viscosity, and temperature.

- Minimum Pulsation : Unique design offers virtually pulseless flow without valves or flexible elements to hinder performance.

- High Temperature Capability : Operating Temperatures to 250o C

- High Volumetric Efficiency : Maximum efficiency is achieved with optimum operating clearances and assured under pressure by built-in alignment dowels.

- Precision construction : Ground and Lapped components for close of operating clearances

- Maximum Life : Only three moving parts, components are through hardened tool and die steels to 60Rc or better.

Technical Specifications of PU Pumps :

- Pump Type : Rotary external spur gear, single stream

- Rotation : Refer to Pump drawing

- Operating Speed : 3-180 rpm depending upon application conditions and fluid viscosity

- Temperature : 250oC

| Model | Capacity | DIS Pressure (Kg) | Torque | Maximum RPM |

|---|---|---|---|---|

| PL-3 | 3 cc/rev | 20 | 80 lbs-in | 180 |

| PL-6 | 6 cc/rev | 20 | 80 lbs-in | 180 |

| PL-12 | 12 cc/rev | 20 | 80 lbs-in | 180 |

| PL-20 | 20 cc/rev | 20 | 80 lbs-in | 180 |

| PL-40 | 40 cc/rev | 20 | 80 lbs-in | 180 |

| PL-60 | 60 cc/rev | 20 | 80 lbs-in | 180 |

| PL-80 | 80 cc/rev | 20 | 80 lbs-in | 180 |

| PL-100 | 100 cc/rev | 20 | 80 lbs-in | 180 |

Benefits of PU Pumps :

Polyurethane (PU) pumps offer several advantages across various industries due to the unique properties of polyurethane materials. These benefits make PU pumps a preferred choice in industries such as mining, chemical processing, food and beverage, pharmaceuticals, and wastewater treatment, where durability, chemical resistance, and versatility are crucial. They offer precision in application, reduced waste, and improved efficiency in processes involving polyurethane.

- Durability and Wear Resistance : Polyurethane has excellent abrasion resistance, making PU pumps highly durable in applications involving abrasive materials. This results in longer pump life and reduced maintenance costs.

- Chemical Resistance : PU pumps are resistant to a wide range of chemicals, including oils, solvents, and fuels. This chemical resistance ensures the pumps can handle aggressive fluids without degrading.

- Flexibility : Polyurethane is a flexible material, which allows PU pumps to operate efficiently in applications requiring flexibility, such as peristaltic pumps or applications with variable fluid viscosities.

- Noise Reduction : The inherent damping properties of polyurethane reduce noise and vibration during pump operation, contributing to a quieter working environment.

- Energy Efficiency : The flexibility and resilience of polyurethane reduce friction losses within the pump, enhancing overall energy efficiency.

- Temperature Resistance : PU pumps can operate effectively across a wide temperature range, maintaining performance in both low and high-temperature conditions.

- Corrosion Resistance : Polyurethane is resistant to corrosion, which is particularly beneficial in environments where the pump is exposed to corrosive fluids or atmospheres.

- Versatility : PU pumps are suitable for a variety of applications, including the pumping of slurries, chemicals, water, and food products. This versatility makes them a valuable choice in many industries.

- Ease of Manufacturing : Polyurethane can be easily molded into complex shapes, allowing for the customization of pump components to meet specific application needs.

- Cost-Effective : Due to their longevity and reduced maintenance needs, PU pumps offer a cost-effective solution over the long term compared to pumps made from other materials.

How to Choose the right PU Pump?

When selecting a PU pump for casting, consider the following factors :

- Viscosity of the Resin : Ensure the pump can handle the specific viscosity of the polyurethane resin used in your process.

- Flow Rate Requirements : Determine the required flow rate and choose a pump that can deliver it accurately.

- Mixing Requirements : If your process involves mixing multiple components, select a pump with appropriate mixing capabilities.

- Material Compatibility : Verify that the pump materials are compatible with the chemicals in the resin.

- Maintenance and Durability : Consider the ease of maintenance and the expected lifespan of the pump in your specific application environment.